4x4x4 LED-cube based Arduino and Flower protoboard

January 12, 2019

Flower ProtoBoard Evolutionary History

January 12, 2019We are always wondering what kind of protoboard is the most convenient for us to use. How can we improve the traditional protoboard? We have some ideas such as saving solder, supporting SMD and facilitating the soldering, but which are far more enough, and we need more ideas for this revolution. There are some good suggestions for Flower ProtoBoard, and here we want to share with you what we have added to Our Plan. If you have any suggestion to improve ProtoBoard, share with us. Anything is welcome ! Once your suggestion is added to our improving list, we will send a sample to you as a gift.

The Suggestion from Ross, thanks ross.

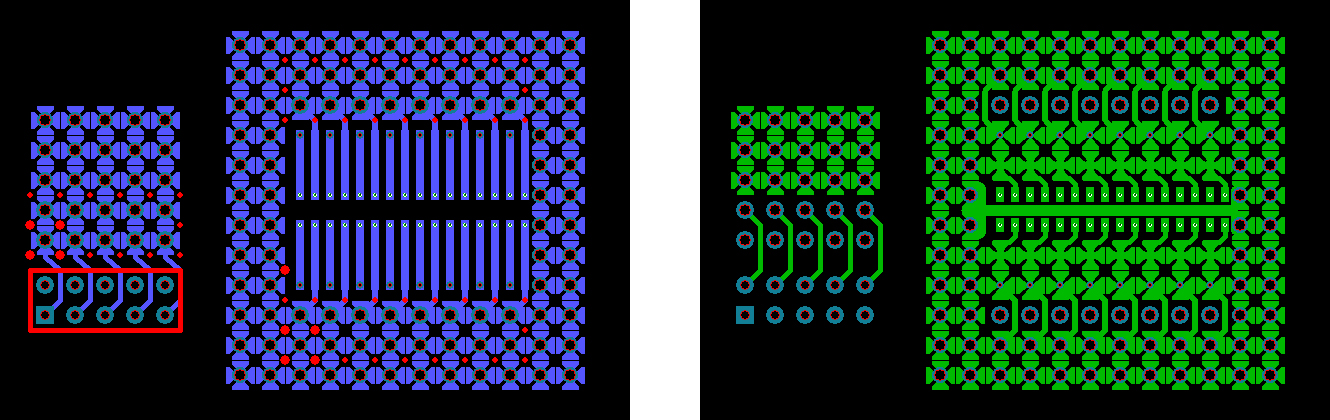

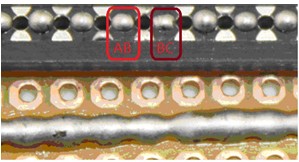

Q: ‘ if the holes are plated through and connect with the flower pads on the second side? ’

A: Yes, the holes are plated through and connect with the flower pads on the second side. So it can not be point-to-point wired on double side. In fact, if this board can be accepted by everyone, we intend to launch a series. Double side flowers and holes not plated through is in our plan. You can double side wiring on that board. The Suggestion from Andrew, thanks Andrew.

Q: ‘ some way of supporting the weird pin spacing of the L298 h-bridge motor driver would be a -wonderful- addition. ‘

A: That‘s really a good suggestion. Your feedback will be included in our Flower ProtoBoard serise list.

Also Suggestion from Andrew, thanks Andrew. The key would be to be able to support more than just the L298 (the package is called a Multiwatt package, if I remember right); there are a few other IC devices in that (or similar) packages; many such are made by ST and other companies, and include other kinds of motor drivers and controllers, as well as audio amplifiers and others. If it were possible to set up a “staggered” line of these holes along the edges – however you do it – you could allow for devices with different pin amounts, as well as for connecting up multiple devices (for instance, someone might want to prototype a stepper driver board or something, maybe for a RepRap machine – and want to use multiple L298 ICs to do so; in my case, I could see wanting multiple L298 ICs, one per motor with each IC being used in “bridged” mode for 4 amps of current capability). I say put them at the edge for a reason: It is also difficult (for some wacky reason) to find multiwatt heatsinks (or profile aluminum to cut your own); by putting them at the edge of the board, you could open the possibility that the ICs could be bolted to a metal case, or a larger heatsink, in such a manner that may not be possible if the ICs were in the middle of the board. That’s just my opinion and idea of course; may your engineers would have a better idea…?

A: Your suggestions really inspiration to me. Placed a row of ‘Multiwatt package’ at the edge of the board is a good ideal. It will easy to place heatsinks. But it still have some problem. You will hard to wrie. So maybe place package in the middle of the board, and customize the heat sink by us is a better way. If so, we can set aside the position of the heat, and it wil easier to mount.

The technical discussion at AVRFreaks, thanks Nard

1. It’s a giant step forward in pad-shape in years. See the attached “various” picture

2. 1206 shape is doable but 0805 is better. SOT23: a 45 degr orientation has been suggested, but I’d rather use orthogonal orientation. But that’s a matter of taste. SOT223 is easy to use.

3. The SOIC area: we AVRfreaks need 4 more pins to use a 90PWM3. See picture.

4. Tracks from header-holes to pads are very thin: 0.2mm ? I’d prefer a wider track.

5. Ross suggested a non-plated through version: I understand the why, but the “price” is loss of ruggedness. Maybe this suggestion helps: use a 3mm spiral steel drillbit, put it on a hole of which you’d like to get rid of the plated through hole, a few turns by hand suffice. Of course the four leaves of the flower are no longer interconnected but a small blob of tin will re-establish that connection.

6. Arduino-shields are a market but so are Eurocards: 100x160mm. No competion to eachother, just an extra market segment. As a price indication: I pay €2.50 for a plated through, square pads Eurocard, FR4 material. A slightly higher price for a Euro-flower card would be acceptable.

The Review from julien gingras, thanks julien.

A: Nice works ! Thanks for your effort. We will publish your review on our blog later. You suggestion

‘holes in the flowers not plated that way top and bottom would be seperated and could densify component.’

is very useful. We have designed a version used double side and sepreated, which was under testing!

I think it’s no problem we will send you more Flower Series or others cool products to you for review in future.

Thanks your effort again, Happy new year!

We are looking forward more idea from you !